Sabirah is a Master Scheduler at an extreme sports company. She oversees a number of project schedules but does not manage any one project directly. One group is building a new parachute harness for recreational skydiving. The harness promises to be more comfortable and more adaptable to the new styles of skydiving and base jumping being pioneered by thrill seekers.

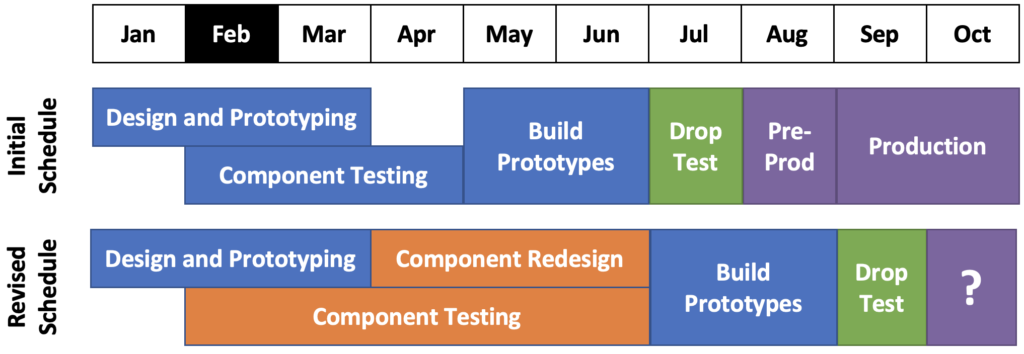

The company has an agreement with a manufacturer to start production in September. Since the harness requires novel fabrication techniques, the manufacturer must shut down their other operations for two months to concentrate on this one order. That makes it essential for design, prototyping and drop testing (where they throw a parachute-laden mannequin out of a plane) to complete by late July. The month of August will be used to transmit final designs, and complete pre-production legal and contractual paperwork.

In February, the parachute group failed to update their schedule. When Sabirah inquired why, the product team, who manages the project up to production, responded that they were evaluating the schedule. They would have a full update next month. For Schedule Managers, this non-answer suggests real trouble. Sabirah dove straight towards the problem, picking up the phone and calling the Product Manager. After the usual pleasantries she asked, “So Don, what happened during component testing last week?”

“We discovered that a buckle isn’t strong enough and needs to be redesigned. The new buckle shape will also force us to redesign part of the harness. So, building the prototype may take a little longer and testing might be delayed.”

Sabirah knew that these changes were not out of the ordinary. She also knew that delay was a certainty, not a possibility. “Okay,” she replied. “How much more time will we need to redesign the harness and build prototypes?”

“We’re still evaluating the schedule, but we think we can make up the time during testing.”

Again, Sabirah spotted the deflection. “Okay, let’s meet tomorrow morning and figure it out.”

“I don’t know if we’ll be ready to meet then,” Don said. “We still need time to study the schedule.”

Sabirah pressed the matter gently. “That’s okay. I’ll help you figure out what’s going on. We can start this afternoon if the team is free.”

A deep dive into the schedule revealed two problems. First, the project had separate schedules for the overall project and for prototyping. These schedules did not marry up well, making it hard to figure out what was dependent on what. So, the first order of business was to clean up and consolidate the two schedules. This done, Sabirah and the project team determined that redesigning the prototype would take two additional months. Don remained hopeful that they could make up the time during drop testing. Here lay the second problem. Drop testing was only scheduled to take a month.

The earliest the prototype could ship for drop testing would be September. There is simply no way a one-month test event can be collapsed enough to make up a two-month delay.

Questions to Consider

- Before discussing the project with Sabirah, did Don realize that redesigning the buckle would unavoidably delay production?

- Don’s wait and see approach is an example of passive schedule management. If Sabirah had not intervened, what dates and events would have exposed the delay to production? Who would be alerted to the delay and when?

- What are the tradeoffs to recognizing the delay now versus recognizing the delay at some later date?

- Sabirah’s company never sells an untested product. However, the company has one very high-risk option for meeting the production date. Assuming the schedule is incompressible and that no activities are descoped, how can Sabirah crash the schedule to begin production as planned? What large financial risk would the company have to assume? What factors would need to be weighed when considering this high-risk path?